On my trip to Italy with Sam’s Club cheese buyers, we visited cheese producing factories. One of the factories we toured was IGOR- makers of Gorgonzola. For 3 generations, the Leonardi family have run the Gorgonzola business. This was by far the largest, most modern factory of those we visited. You’ll see in my Provolone and Asiago posts that most of the cheese production companies in Italy don’t have such state-of-the-art equipment.

A little background on Gorgonzola from Wikipedia:

Gorgonzola is a veined Italian blue cheese, made from unskimmed cow’s and/or goat’s milk. It can be buttery or firm, crumbly and quite salty, with a ‘bite’ from its blue veining. It has been made since the early Middle Ages, but became marbled with greenish-blue mold only in the eleventh century. It is frequently used in Italian cooking. The name comes from Gorgonzola, a small town near Milan, Italy, where, it is reported, the cheese was first made in 879; however, this claim of geographical origin is disputed by other towns.

There are two types of gorgonzola. The one pictured on the left is “Dolce” (creamy) and the one pictured on the right is “Piccante” (chunk form). Sam’s Club currently carries the Piccante (also known as Mountain Gorgonzola), and they carry the creamy Dolce type during the holidays too.

The making of Gorgonzola is a mostly automated, sophisticated, modern process. Everything is hygiene-controlled so that contamination is not introduced. To enter the factory, you must go through machines that wash your hands (and then check to make sure your hands are free of germs). The machine even scrubs the bottoms of shoes, and then you must wear boot coverings over your feet.

A control room checks the temperature and humidity of the rooms in the factory.

A laboratory is in place for testing milk samples too. It’s a 24 hour/day process for making sure that the machines “respect” what the process is for each step of making the Gorgonzola. The management is so concerned with the outcome that only a couple of people actually have passwords for computers in the most critical stages of the process.

To begin the process of making gorgonzola, there is 24 hours of automated production. Milk is heated in very large metal containers; then Penicillium roqueforti and starter is added to the milk. Large metal paddles stir the mixture, and it travels from one container to another. Rennet is also added during this process, and curds begin to form. Machines handle the large curds gently to keep openings present in the curds where the mold can grow.

At this point, the curds are separated from the liquid and moved to a machine where they will be pressed together to create wheels of cheese.

The wheels are then covered in sea salt.

Then they’re placed into a warm room with controlled humidity for about a week… it’s important that salt in the cheese doesn’t suck humidity out of the air and bring moisture into the cheese.

When it’s time for aging, air holes are poked into the wheels to allow mold to grow inside the cheese.

The wheels are then transferred to the “maturity department,” a cooler room with a controlled environment… and it is here that the mold begins to grow!

Machines re-position the cheese regularly during the aging process, and the wheels are washed (also by machine) 2 to 3 times during the maturity process. Aging takes about 55 days for Gorgonzola cheese.

IGOR turns out 200,000 of these giant wheels of cheese in 50 days’ time. They have multiple machines that cut or crumble the cheese, depending on how it’s packaged, and then it’s ready to be shipped all over the world.

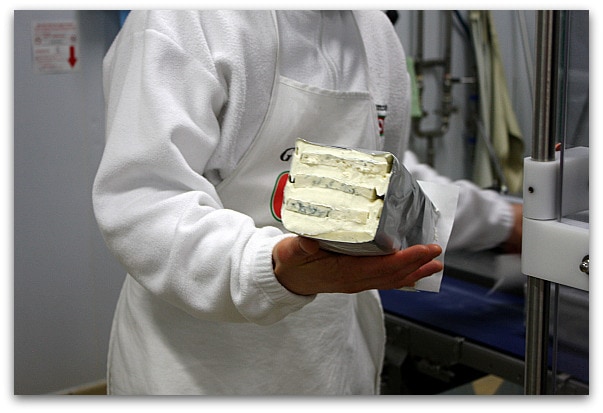

Guess what this is? Gorgonzola layered with mascarpone cheese. Can you even imagine what that must taste like?! Sam’s Club needs to carry this too!

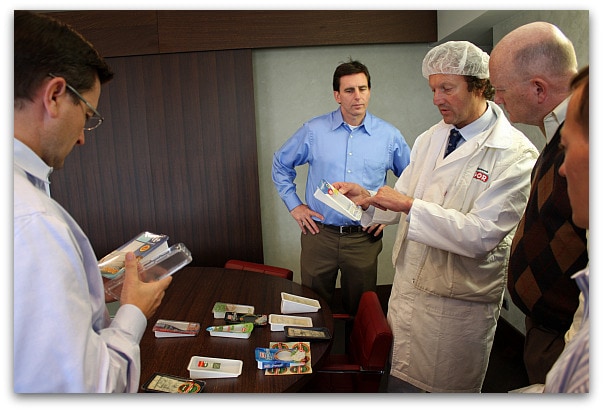

Here’s where the business takes place… the cheese buyers meeting with one of the IGOR owners, who is sharing new ideas for packaging. This is where Sam’s Club makes decisions about what new products they might like to carry in their store.

This factory tour was an eye-opening experience. I never imagined it was such a delicate, controlled process to create Gorgonzola cheese. I love it in salads and pastas, and I now have a greater appreciation for all that goes into creating its unique flavor. We got to taste an abundance of appetizers at the factory that were made with IGOR Gorgonzola. All of it was absolutely incredible (Gorgonzola lover here), but I was a little bit on Gorgonzola-overload after a while. You can only have so much of it before you need to move onto something else! Here are a couple of ideas for using Gorgonzola in appetizers…

With chunk gorgonzola (also called Piccante or Mountain gorgonzola), simply cut a small cube and skewer with grapes. The sweetness of the grapes balances out the tangy flavor of the gorgonzola, and it makes a quick & easy appetizer.

Roll out pre-made pizza dough and cut out small rounds. Top with a small amount of pizza sauce, mozzarella and a sprinkle of gorgonzola and bake until crust is golden and cheese is melted. And if you’re a real lover of Gorgonzola cheese, spread on some creamy gorgonzola & then top it with chunk gorgonzola too!

More recipes with Gorgonzola that you might like:

Grilled Fig Bruschetta

Crostini with Gorgonzola & Fig Jam

Cranberry Spinach Salad with Gorgonzola

Blood Orange Spinach Salad

Fresh Figs with Gorgonzola & Prosciutto

Gorgonzola- Stuffed Beef Burgers w/Sauteed Wild Mushrooms

Interesting article. I developed a taste for Gorgonzola while living in northern Sardinia years ago. It was home made in small batches, a far cry from what is seen here. I make my own yogurt and simple cheeses; store bought is good, but if I’m ever to get that fresh Gorgonzola taste again I’ll have to take on the challenge of making it.

@Ed Magowan, After seeing what all was involved in the process, I can’t imagine making it myself! I’d love to explore the possibility of making some cheeses at home though.

Wow! I had no idea how detailed of a process making this particular type of cheese is. I would also like to know if your company is hiring…I would love to travel the world tasting of wonderful foods and writing about!

@Ck, Not hiring at the moment 🙂 I must say, the food industry is a fun one to be involved in. I love what I do!

I’m completely craving Gorgonzola now..and with mascarpone…oh heavenly! : )

Sounds like a great experience!

What a fantastic trip & opportunity. I, too, am a big fan of Gorgonzola (I’ve eaten & cooked with the layered Gorgonzola/Mascarpone before and it’s sinfully delicious.) Really great post. Look forward to the next one.

Oh my gosh… I want to attack that factory! How neat, though. I honestly never put too much thought into the “molding” process of a blue cheese!

I love Gorgonzola cheese, sort of think of it as bleu cheese lite! But cheese is cheese and I mostly love the story behind your visit; what a great trip and experience.

Oh, I would have been in cheese heaven here Lori! What a great trip you took! Love seeing all the pics 🙂

Gorgonzola is such a fantastic and versatile cheese- I love hearing and seeing how it’s made!

@A Boston Food Diary, Butter in any of the recipes on my site is “salted,” unless noted specifically as unsalted. Thanks for asking 🙂